Price

contact usCategory

OTHERSExport Type

Presence / Movement of natural personsCovered Industries

Looking for partner in

We have been manufacturing solid sticks by a group of experts including faculty members, researchers and skilled workers since 5 years ago. All of the development processes done step by step from laboratory production to mass production according to standards to achieve reliability of products.

Our product is an encapsulated solid lubricant in a thermosetting polymeric binder with no oil or liquid components, formed into blocks in order to be used in lubrication of wheel flange-rail gauge corner interface for locomotives, metro wagons, trams and other devices running on steel rails. It is a laboratory tested and field-proven solid stick with the best lubricity, retentivity and optimized longevity and made according to EN 16028:2012, to resist wear. This dry solid lubricant is applied to the wheel flange without migrating to the wheel tread or railhead and therefore with no impact on traction or braking.

1-High lubrication (coefficient of friction< 0.15) 2- High temperature resistance (up to 150 °C) 3-Low water absorption (<1 %) 4- Flame retardant 5-Desirable longevity 6-Different shapes and sizes 7-Non-toxic

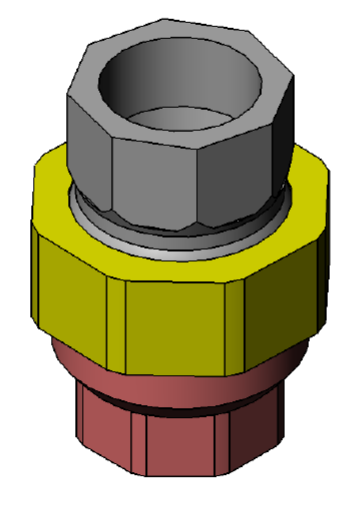

Solid lubrication system is able to implement in all railcars such as locomotives, metro wagons, trams and other devices running on steel rails. It is also useful for gantry and overhead cranes and kiln dryers. We are able to provide all devices related to this lubrication system such as applicator, spring and brackets.

Our products increase the longevity of wheel flanges of trains and rails and significantly reduce the consumption of lubricant compared to the use of synthetic grease. Other benefits of our solid sticks are: • Reduced energy consumption • Reduced repair and maintenance costs • Lowered financial losses • Increased safety of operation (fewer cases of derailment) • Reduced operation noise • Significantly reduced contamination We have produced our parts based on DIN EN 16028 with the highest quality and lower price in comparison to other suppliers. Also we can export our products all over the world. Furthermore, we are able to optimize our products based on customer needs.